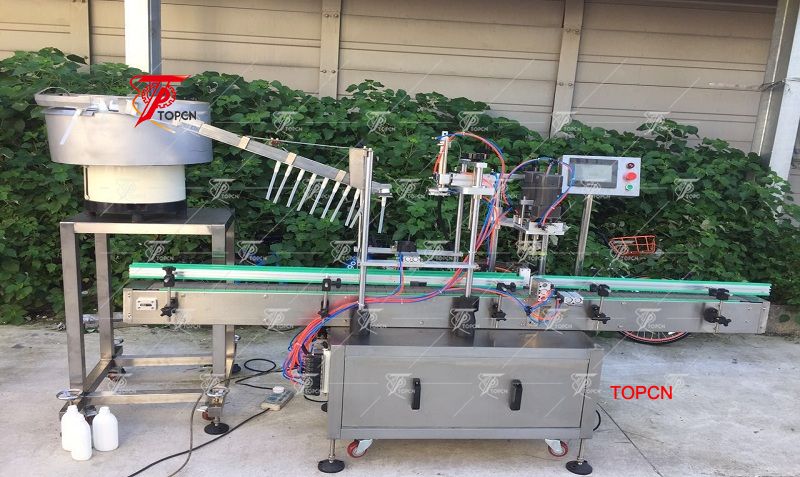

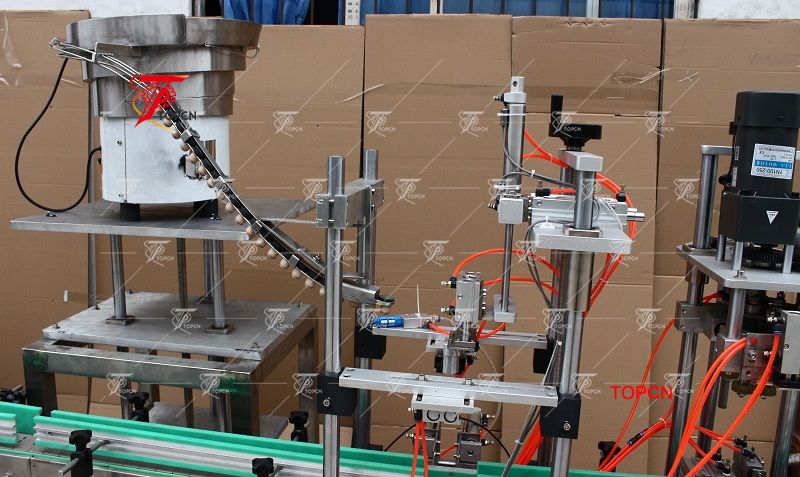

Automatic Spray Bottle Filling Capping and Labeling Machine

- Application

- Description

- Products Parameters

- Video

- Package&Shipping

- FAQ

Automatic spray bottle filling capping and labeling machine depends on the different products and various filling requests of the customers, for example, high viscosity or sticky cream, paste, such as, tomato paste, ketchup, jam, sauce, butter, chocolate paste, cosmetics cream, etc., low viscosity liquid products, such as, juice, beverage, shampoo, lotion, laundry detergent, dish detergent, wine, soybean sauce, vinegar, edible oil,cooking oil, drinking water, etc., and liquid chemical products, liquid pesticide, liquid fertilizer, liquid medicine, etc.

Depends on the different products and various filling requests of the customers, for example, high viscosity or sticky cream, paste, such as, tomato paste, ketchup, jam, sauce, butter, chocolate paste, cosmetics cream, etc., low viscosity liquid products, such as, juice, beverage, shampoo, lotion, laundry detergent, dish detergent, wine, soybean sauce, vinegar, edible oil, cooking oil, drinking water, etc., and liquid chemical products, liquid pesticide, liquid fertilizer, liquid medicine, etc.,

*** Our company can design and produce suitable filling machines with matched filling system, such as, underflow pump, free-flow pump, flow-meter pump, piston pump, gear pump, screw pump, peristaltic pump, ceramic pump, electric weighs, etc., and depends on the filling volumes and production amount, the filling machines can be equipped with 1, 2, 4, 6, 8, 10, 12, 16 filling nozzles.

*** The operation system with advanced PLC+ touch screen, electrical and pneumatic components can be with good quality domestic brands, joint-venture brands and imported brands, such as WEINVIEW, SIEMENS, SCHNEIDER, MITSUBISHI, PANASONIC, AIRTAC, etc.,

*** The parts contact with products are made of high-class SUS 304, SUS 316 and SUS 316L. Sanitary comply with GMP standard. The machines with reasonable structure, advanced technology, high precision filling, stable performances, simple and easy operation, can be used independently, and can also equipped with automatic bottles unscrambler, automatic stopper pressing machine, automatic caps screwing machine, automatic caps crimping machine, automatic bottles sealing machine, automatic date/batch codes printer, automatic carton/box loading machine, to be automatic filling production line.

*** With a high automation degree, finished products with a high qualified ratio, significantly saving manpower cost.

Model No | TPAF Series |

Name | bottle filling capping and labeling machine, filling capping machine, filling capping and labeling machine, spray bottle filling, automatic filling capping and labeling machine, |

Filling Heads / nozzles Amount | 2 4 6 8 10 12 16 |

Filling dosage | 5-50ml, 50-500ml, 100-1000ml, 500-5000ml |

Hopper Capacity | 50L--150L |

Filling Speed | 1000-5000B/H (Depends on the filling heads amount of the filling machine, and the filling volume ) |

Accuracy | ± 1.0%(on the base of 1000ml) |

Control system | PLC & Touch screen |

Power supply | AC220V 50Hz 1phase/AC380V 50HZ 3phase |

Air consumption | 0.3-0 .7 Mpa |

G.W. | 450KG--1200KG |

Power | 0.5KW--2.0KW |

Dimension | customized |

bottle filling machinery production line pharmaceutical production line for bottling spring water

Shampoo Lotion Detergent Bottling Production Line

Capping machine for cosmetic amber glass dropper bottle for essential oil

1. DELIVERY LEAD TIME:

35-50 WORKING DAYS FOR THE SEMI AUTOMATIC MACHINE AFTER RECEIVED DEPOSIT

2. TERMS OF PAYMENT

BY 40% IN ANVANCED, THE BALANCE 60% BY T/T BEFORE SHIPMENT

3. PRICE VALID UNTIL

30 DAYS.

4. PACKING: WOODEN WITH STRONG SEAWORTHY PACKING SUITABLE FOR EXPORT

5. PORT OF SHIPMENT

GUANGZHOU or SHENZHEN PORT

Q: What should I do to choose the best machine for us?

A: 1) Tell me the material you want to fill, we'll choose the suitable type of machine for you to consider.

2) After choose the suitable type of machine, then tell me the filling capacity you need for the machine.

3) At last tell me the inner diameter of your container to help us choose the best diameter of the filling head for you.

Q: Do you have manual or operation video for us to know more about the machine?

A: Yes, we will send you the manual and operation video after you ask for us. &

Q: If there's some spare parts that broke,how to solve the problem?

A: Yes, we will send you the manual and operation video after you ask for us.

Q: If there's some spare parts that broke,how to solve the problem?

A: First of all, please take the pic or make a video to show the problem parts.

After the problem is confirm from our sides, we'll send you the spare parts for free, but the shipping cost should be paid by your side.