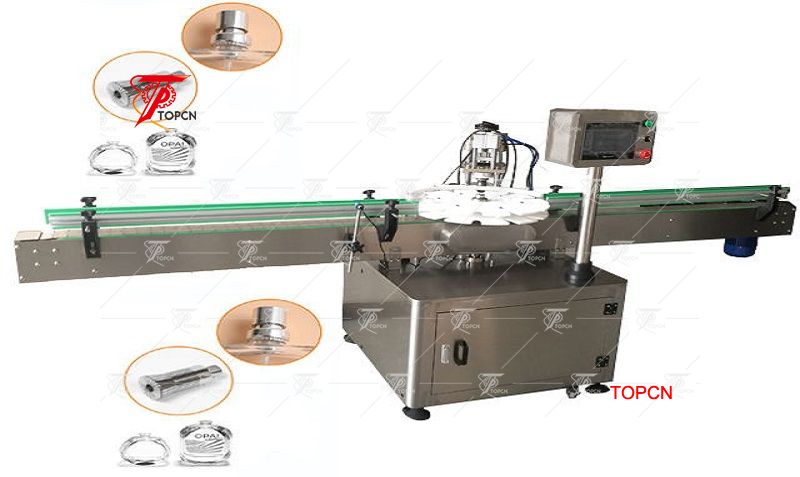

Automatic rotary type perfume crimp equipment glass bottles perfume crimping machine

- Application

- Description

- Products Parameters

- Video

- Package&Shipping

- FAQ

This perfume capping machine is widely used in the perfume cap closing of spray bottle caps, uses the clamp to close the cap and fasten it on the edge of bottle.

► Adopt pneumatic drive, without the electrical power, the whole machine is composed of machine body, table surface, clamping device and pneumatic control system.

► It is a kinds of clamping type cap closing machine, use the scalable method to close the cap and fasten it on the edge of bottle mouth, even cap closing with good sealing performance, lock mouth fastness and beautiful, accurate cap positioning without abrasion on the surface, convenient operation and maintenance, high speed.

►Automatic rotary type perfume crimp equipment glass bottles perfume crimping machine suitable for cap closing of spray type caps, such as perfume bottles, oral liquid bottles, ampere bottles such as aluminum cover lock mouth of the bottle. It use to seal valve cover of all kinds of perfume bottle, widely used in the beverage and perfume packaging lines.

Automatic rotary type perfume crimp equipment can working with

Manual magnetic pump filling machine, then to capping.

manual perfume filling machine manual vacuum filling machine

Semi automatic Four Nozzles Perfume Vacuum Filling Machine

►all use compressed air as power, electrical circuit control, so fast, high efficiency.

► centralized control by the computer, man-machine interface operation, there is no complex circuit, the operator is not too high.

► in the case of emergency stop, just press the emergency stop switch, the machine reset to stop.

►before the inspection and operation sequence Before starting the machine model TPCM-P2 ROTARY crimping equipment must be checked whether the normal part, so as to avoid mechanical failure or personal injury accidents.

1, front and rear clamping handle is clamped.

2, three-way access to the three-way clamp is clamped.

3, fixed fast-loaded components are clamped.

4, connected to air source, pressure <8㎏ / c ㎡, air pressure 5-6㎏ / c ㎡.

5, open the air source switch.

6, turn on the power switch.

Model No | TPCM-P2 |

Diameter of bottles | 15mm 18mm 22mm |

Power supply | 220V/50HZ/Single phase |

Power consumption | 0.75Kw |

Air pressure | 0.4-0.8Mpa |

Capacity | Around 20-30pcs/min |

Overall dimensions | 2000*1450*1700mm |

Weight | 550KG |

1. DELIVERY LEAD TIME:

5-7 WORKING DAYS FOR THE SEMI AUTOMATIC MACHINE AFTER RECEIVED DEPOSIT

2. TERMS OF PAYMENT

BY 40% IN ANVANCED, THE BALANCE 60% BY T/T BEFORE SHIPMENT

3. PRICE VALID UNTIL

30 DAYS.

4. PACKING: WOODEN WITH STRONG SEAWORTHY PACKING SUITABLE FOR EXPORT

5. PORT OF SHIPMENT

GUANGZHOU or SHENZHEN PORT

Q: What should I do to choose the best machine for us?

A: 1) Tell me the cap you want to close, we'll choose the suitable type of machine for you to consider.

2) After choose the suitable type of machine, then tell me the capping capacity you need for the machine.

Q: What normal size of the crimping head?

A: 3 sizes are normal size:15mm, 18mm and 22mm, other size need 7 days to customize.

Q: Do you have manual or operation video for us to know more about the machine?

A: Yes, we will send you the manual and operation video after you ask for us.

Q: If there's some spare parts that broke, how to solve the problem?

A: Yes,we will send you the manual and operation video after you ask for us.

Q: If there's some spare parts that broke, how to solve the problem?

A: First of all, please take the pic or make a video to show the problem parts.

After the problem is confirm from our sides, we'll send you the spare parts for free, but the shipping cost should be paid by your side.