High Speed Inline Automatic Bottle Capping Machine with Conveyor

- Application

- Description

- Products Parameters

- Video

- Package&Shipping

- FAQ

The whole automatic capping machine adopts elaborate DIY design.By eliminating unnecessary complex and heavy machinery, it adopts suit type assembly.The maintenance and servicing can be completed without professionals.when it is necessary to replace the product,just make some simple adjustments, it can be immediately put online for production.

The machine is suitable for the duckbill cap,beak cap, spray cap,irregular cap,circular cap in such industries as food, condiment,medicine,wine,oil and cosmetics etc.

The bottle to be rotated is placed on the chain board at the inlet of the equipment (or sent directly to the chain board from other assembly lines), and

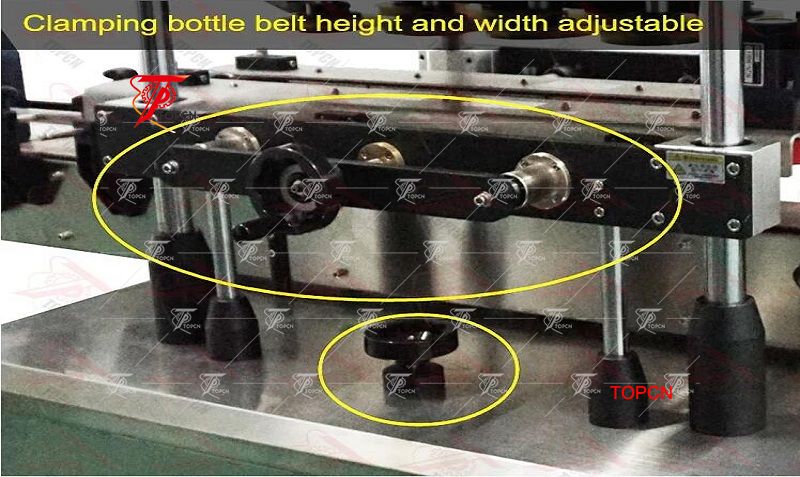

the bottle is divided into equidistant arrangement and into the falling cover area by the distance adjusting device.When the bottle is clamped forward and

moved forward by the two-sided clamping device, the cap is automatically jacketed, the cap is pressed to a pre-tightening state before the cap is rotated,

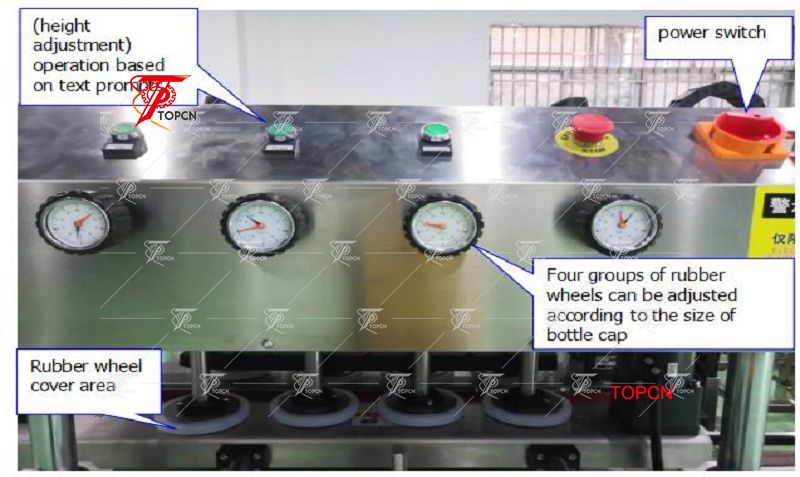

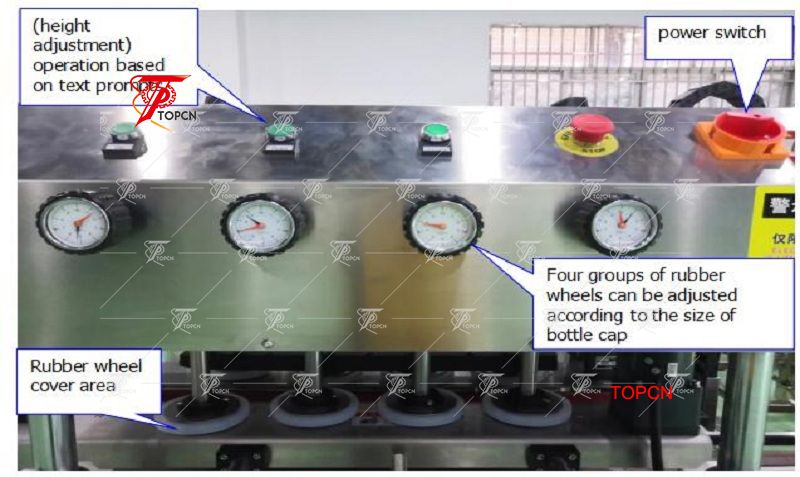

and the cap is tightly rotated on the bottle body under the action of three pairs of high speed rotating wear-resistant rubber wheels.In the process of

rotary cap, the contact between the bottle body and the bottle cap is non-metal parts, which reduces the wear of the bottle body and the bottle cap to the

greatest extent;The whole spinning process has only one moment, with little noise and high speed.This machine is equipped with the most advanced lifting cover

and continuous cover, which overcomes the common shortcomings of this kind of rotary cover machine.

Machine | Full Automatic spindle capping machine | |

Capacity | 70-80 b/m(subject to bottles and cap size) | |

Cap diameter | Φ20~120 | |

Bottle Height | 40~350mm | |

Dimension | L1060*W896*H1620mm | |

Voltage | AC 220V 50Hz | |

Power | 1100W | |

Weight | 500kg | |

Cap Feed system | Elevator feeder | Vibrator feeder |

Dimension | L880×W1000×H2600mm | L800×W600×H1700mm |

Inline Capping Machine With Cap Sorting Elevator

automatic bottle capping machine height and width adjustable

capping machine with conveyor speed is about 70-80 bottles at least.

High Speed Inline Automatic Bottle Capping Machine with Conveyor Working Video

High speed automatic twist off sealing capping machine introduction of each part

Automatic bottle liner trigger capping machine roller how to working

1. DELIVERY LEAD TIME:

35-50 WORKING DAYS FOR THE SEMI AUTOMATIC MACHINE AFTER RECEIVED DEPOSIT

2. TERMS OF PAYMENT

BY 40% IN ANVANCED, THE BALANCE 60% BY T/T BEFORE SHIPMENT

3. PRICE VALID UNTIL

30 DAYS.

4. PACKING: WOODEN WITH STRONG SEAWORTHY PACKING SUITABLE FOR EXPORT

5. PORT OF SHIPMENT

GUANGZHOU or SHENZHEN PORT

Q: What should I do to choose the best machine for us?

A: 1) Tell me the material you want to fill, we'll choose the suitable type of machine for you to consider.

2) After choose the suitable type of machine, then tell me the filling capacity you need for the machine.

3) At last tell me the inner diameter of your container to help us choose the best diameter of the filling head for you.

Q: Do you have manual or operation video for us to know more about the machine?

A: Yes, we will send you the manual and operation video after you ask for us.

Q: If there's some spare parts that broke,how to solve the problem?

A: Yes, we will send you the manual and operation video after you ask for us.

Q: If there's some spare parts that broke,how to solve the problem?

A: First of all, please take the pic or make a video to show the problem parts.

After the problem is confirm from our sides, we'll send you the spare parts for free, but the shipping cost should be paid by your side.