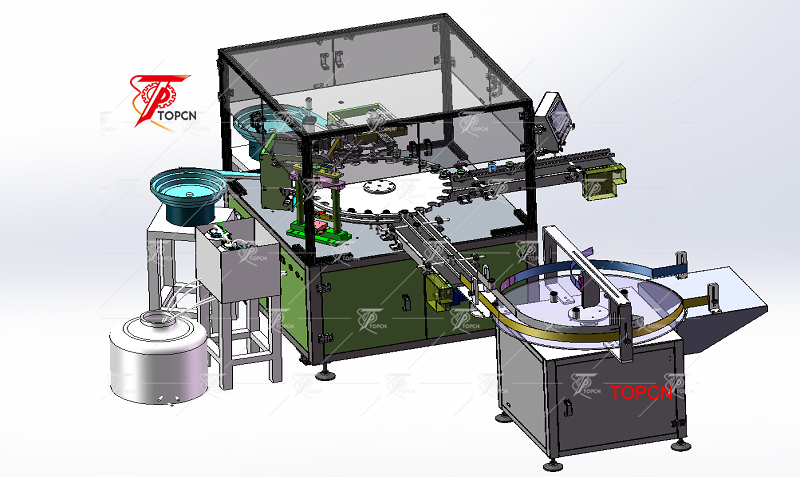

Automatic injection vial filling stoppering and capping machine

- Application

- Description

- Products Parameters

- Video

- Package&Shipping

- FAQ

Automatic injection vial filling stoppering and capping machine is the one that Maximizing output and simplify changeovers. We TOPCN has been developing the machinery in dosing small bottles like filling Perfume、essential oil、E-liquid and other daily use fluid materials.

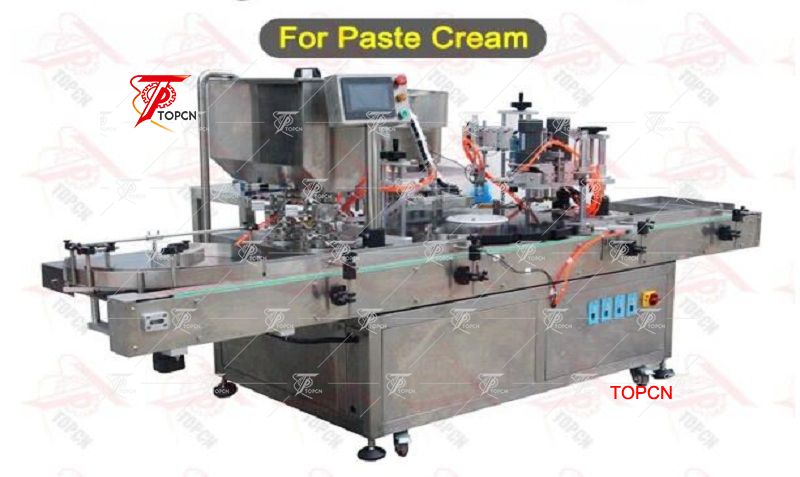

►This machine adopts advanced PLC+Touch screen operation system, easy to operate and maintain.

►injection vial filling machine can fill various liquid products, such as, medicine liquid, liquid essence, E-liquid, perfum, eyedrops, into small bottles, then, feed and press the rubber stoppers, feed and crimp the aluminum caps automatically.

► With high filling precision, all the parts contact with products are made of stainless steel 316/316L, sanitary and durable, comply with GMP standard, with CE and SGS certificates.

► vial filling stoppering and capping machine with auger/screw filling device, this machine can fill various powder products.

►This machine can work various bottles, like amber bottles, penicillin bottles, plastic bottles, cosmetics bottles.

►vial filling capping machine can be used independently, and it can also be connected to other machines, such as, bottles unscrambler, bottles labeling machine, ink-jet printer, to be automatic bottling production line.

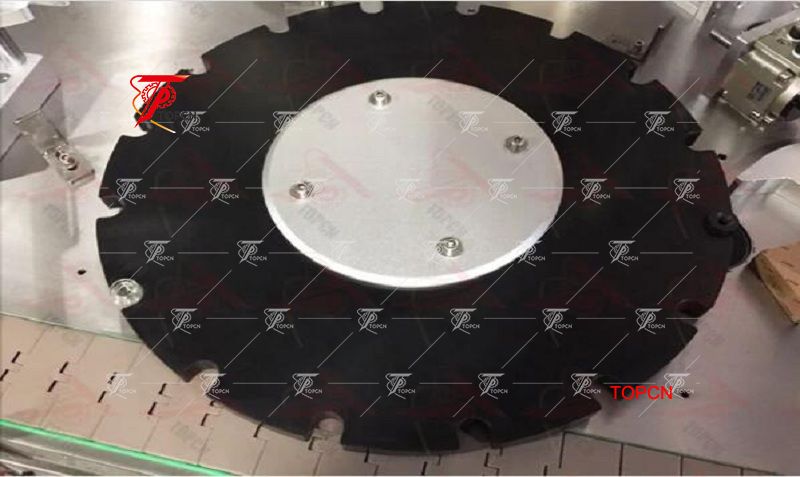

Bottle Star Wheel

Aluminium cap vibrator

peristaltic pump liquid filling plugging capping labeling line with rotary table for extracts aromatherapy flavor essential oils is used for the automatic bottle unscrambling, plugs & caps inserting & rotating by manipulator of eye drops & all kinds of bottle + stopper + cap units. If it’s needed, bottle unscrambling or feeding can be equipped. No filling when no bottle; No plugging when no bottle; No capping when no stopper. The manipulator is used for the plugging & capping structure, and the pass rate gets to more than 99.9%. Its property is stable and reliable. The packing material can be customized, the isolating & protective system can be equipped, and the aseptic eye drop can be produced in this line. As to user’s demand, the configuration can be customized, so the requirement with different specification or different capacities can be satisfied.

Name | Automatic injection vial filling stoppering and capping machine |

Material | The parts contact with products are stainless steel 316/316L, other parts are stainless steel 304 or alloy. |

Products | Small volume liquid or powder pharmaceutical products |

Filling device | Peristaltic pump or magenetic pump |

Stoppers/caps feeding device | Electromagnetic vibrative bowls+photosensor |

Stoppers feeder | 1-2 heads |

Caps feeder | 1-2 heads |

Al cap crimp | 1-2 heads |

Capacity (BPH) | 30-55BPM |

Filling precision | ≤±1% |

Capping pass rate | 99% |

Air pressure | 0.4~0.6MPa |

Voltage | 220V 50Hz 1P |

Power | 1.5kw |

Noise | ≤70dB |

G.W. | 650 kg |

Dimension(mm) | 2500×1200×1950 |

Famous brand electrical parts

Machine frame | SUS304 and SUS316L Stainless steel | |

Peristaltic pump | WATSON MARLOW Peristaltic pump (UK) | |

Main Motor | ABB | Switzerland |

Inverter | Japan | |

Air Switch | Schneider | France |

Contactor | Schneider | France |

Relay | Omron | Japan |

OFA | Autonics | Korea |

Bearing | IGUS | Germany |

CAM indexer | Shangdong | China |

Turntable | Plastic POM | Japan |

Cylinder | AIRTAC | Taiwan |

Touch screen | Siemens | Germany |

PLC | Siemens | Germany |

Servo motor | Delta | Taiwan |

1. DELIVERY LEAD TIME:

35-50 WORKING DAYS FOR THE SEMI AUTOMATIC MACHINE AFTER RECEIVED DEPOSIT

2. TERMS OF PAYMENT

BY 40% IN ANVANCED, THE BALANCE 60% BY T/T BEFORE SHIPMENT

3. PRICE VALID UNTIL

30 DAYS.

4. PACKING: WOODEN WITH STRONG SEAWORTHY PACKING SUITABLE FOR EXPORT

5. PORT OF SHIPMENT

GUANGZHOU or SHENZHEN PORT

Q: What should I do to choose the best machine for us?

A: 1) Tell me the material you want to fill, we'll choose the suitable type of machine for you to consider.

2) After choose the suitable type of machine, then tell me the filling capacity you need for the machine.

3) At last tell me the inner diameter of your container to help us choose the best diameter of the filling head for you.

Q: Do you have manual or operation video for us to know more about the machine?

A: Yes, we will send you the manual and operation video after you ask for us. &

Q: If there's some spare parts that broke,how to solve the problem?

A: Yes, we will send you the manual and operation video after you ask for us.

Q: If there's some spare parts that broke,how to solve the problem?

A: First of all, please take the pic or make a video to show the problem parts.

After the problem is confirm from our sides, we'll send you the spare parts for free, but the shipping cost should be paid by your side.