Here is Customized Stainless Steel Storage Tank Manufacturertalking about What Is The Difficulty In Making Stainless Steel Storage Tanks.

If you have any idea about Stainless Steel Storage Tank For Food, welcome to contact us and discuss.

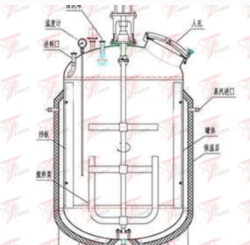

The stainless steel storage tank is a storage tank made of stainless steel. How is stainless steel made as the main material? What are the difficulties?

Stainless steel tanks can withstand higher pressures than conventional rotomolding tanks and are used in many applications. The tank sealing performance is good, so as to avoid the intrusion of harmful substances and mosquitoes in the air, so that the liquid stored in the tank is not polluted by the outside. The above advantages make the stainless steel storage tanks mostly used for storing food, medicine, and used in the wine industry and the dairy industry.

The production of stainless steel storage tanks pays attention to the practical and beautiful view. Therefore, in the production process of stainless steel container equipment, it is very important to pay attention to the difficult processing of raw stainless steel. In the construction of stainless steel, the general steps and procedures are material shot blasting - coating part of the coating - welding, fabrication, installation, pressure test - reprocessing - coating follow-up paint.

The cleaning of the metal surface of the stainless steel tank body, the surface pretreatment of the material, and then the primer is sprayed. After the tank body is completed, the surface of the tank bead is cleaned, and the primer is applied, and then The entire tank is sprayed with intermediate paint and topcoat.

The hardness of stainless steel during processing causes the tool to wear faster and is more difficult to chip. The low thermal conductivity of stainless steel causes plastic deformation of the cutting pin and faster tool wear. The chemical relationship between the tool and the material being processed results in work hardening and low thermal conductivity of the material being processed, which not only causes uneven wear but also causes chipping and abnormal cracking of the tool. When processing stainless steel container equipment, the built-up edge easily causes the small pieces of debris to remain on the cutting edge and cause poor processing of the surface.