Soap Mixer

- Application

- Description

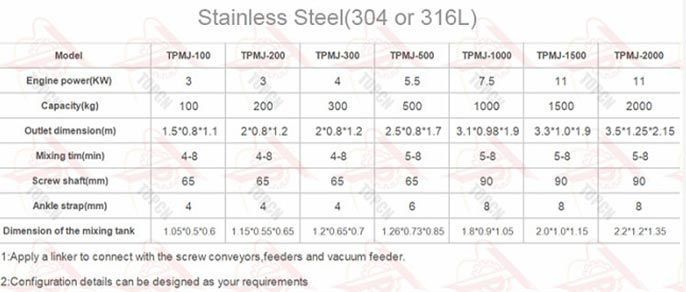

- Products Parameters

- Video

- Package&Shipping

- FAQ

Sigma Mixer Kneader is widely uses for mixing polyester putty, rubber solution, biscuit dough, sauce, polymers etc.

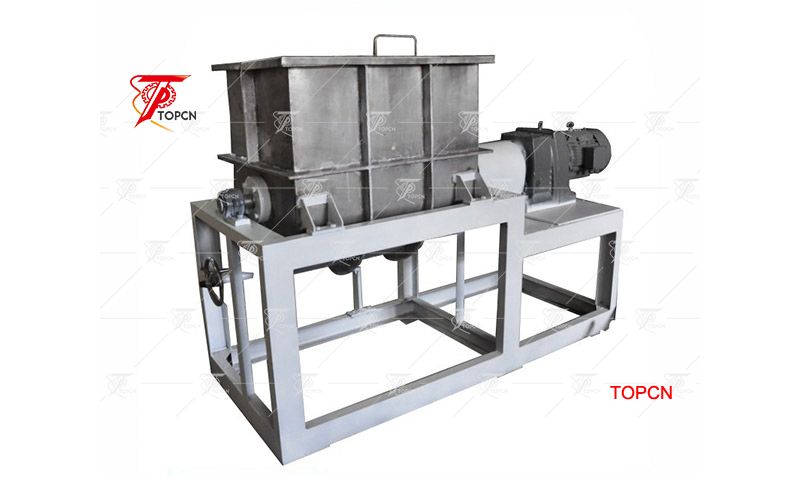

The soap mixer is consist of U trough bowl with two ‘Z’ shape blades each rotates in opposite direction for proper mixing of material. Machine equipped with suitable capacity motor & gearbox decided as per characteristics of the product & process. Equipment is provided with Jacket arrangement for heating or cooling applications. We manufacture Sigma Mixer Kneader in capacity ranging from 5 liters up to 5000 liters.

This machine comprises of a double 'U' shaped container welded and machined together inside which rotates two 'Z' shaped sigma blades in opposite directions. The clearances between the walls and the container are kept to a minimum to ensure maximum efficiency in kneading and mixing. The shafts of the sigma blades are fitted in bearing blocks which are each provided with roller bearings, steel glands/teflon rubber seals for smooth and leakless operations. The kneader is mounted on a sturdy base frame fabricated out of ISMC sections and are free from vibrations. For cooling and heating jackets are provided.

| Name | Qty | Technology parameter |

| Model: 70 mixer | 1 | Mixing various raw materials for producing soap and transparent |

| soap thoroughly and evenly, to refine neat soap, and completely | ||

| mix various auxiliary materials and additives and flavors into neat | ||

| soap to reach the recipe requirements. | ||

| Capacity:70kg/batch | ||

| Soap Fined machine | 1 | Capacity:1000kg/h |

| Motor:15Kw | ||

| Size:2600*1200*1700 | ||

| Weight:1100Kw | ||

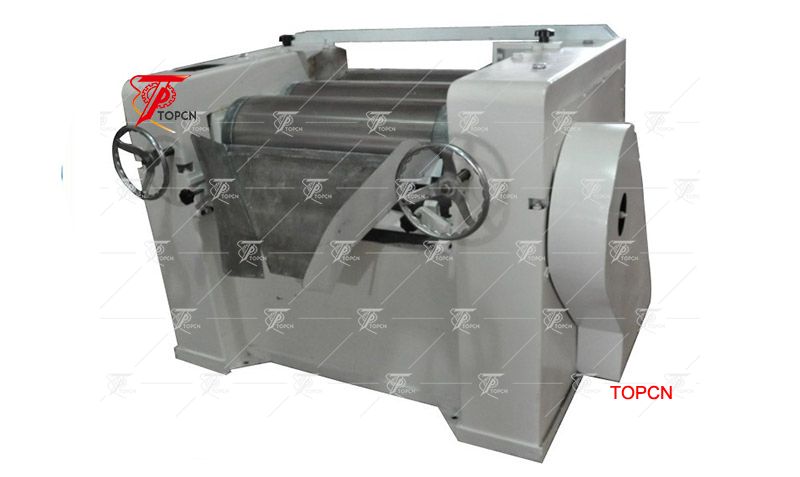

| S260 three roller mill | 1 | Roller diameter:260mm |

| Working face length:695mm | ||

| Power:7.5kw | ||

| Dimension:1650*1350*1100mm | ||

| Weight:2300kg | ||

| C245double vacuum plodder machine | 1 | Capacity:500-800kg/h |

| Powder:7.5kw/15kw | ||

| Dimensions:4000*1000*2450mm | ||

| Weight:2570kg | ||

| Soap printer | 1 | Capacity:60-120pcs/min |

| Power:2.2Kw | ||

| Weight:1000kg | ||

| Dimension:1450*800*1100mm |

1. DELIVERY LEAD TIME:

35-50 WORKING DAYS FOR THE SEMI AUTOMATIC MACHINE AFTER RECEIVED DEPOSIT

2. TERMS OF PAYMENT

BY 40% IN ANVANCED, THE BALANCE 60% BY T/T BEFORE SHIPMENT

3. PRICE VALID UNTIL

30 DAYS.

4. PACKING:WOODEN WITH STRONG SEAWORTHY PACKING SUITABLE FOR EXPORT

5. PORT OF SHIPMENT

GUANGZHOU or SHENZHEN PORT

1, Q: Soap industry production process?

A, Basically, the soap production need 2steps:

a, using all kinds of oil&fast as material to produce semi-finished soap noodle;

b, using seme-product soap noodle to produce end bar soap.

2, Q:What is the kinds of the soaps?

A: For convenience, we separate the soap into two kinds, toilet soap for washing hand&taking bath, herbal soap, hotel soap, antiseptic soap are included;

The second kind is laundry soap for washing clothes, etc.

3, Q: What kind of oil is suitable for soap production?

A: All kinds of vegetable oil and animal fats are usable, palm oil, cotton seed oil, tallow oil, coconut oil, sunflower oil, etc.

4, Q: What is the floor of the workshop size?

A: For oil line: 35*7m with height 7m;

For soap noodle line: 25*3m with height 4m.

5, Q: What is the formula?

A: Raw material is oil, caustic soda and salt; semi-product is soap noodle, perfume and color.

Accurate formula based on your local market's request is available after confirmation of order.

6, Q: How about the Engineer and technique support?

A: 1, We would send engineer overseas for machine installation, staff training and production test running, till your own staff can operate the machine well and product out qualified soaps.

2, During the life-span of our machines, we should give consistent technique support and service, and we are pleasure to be on service of you. (24hours on line)