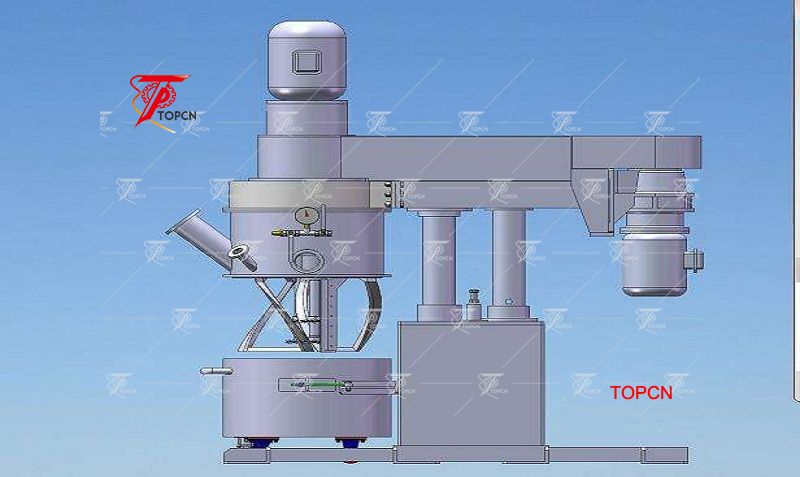

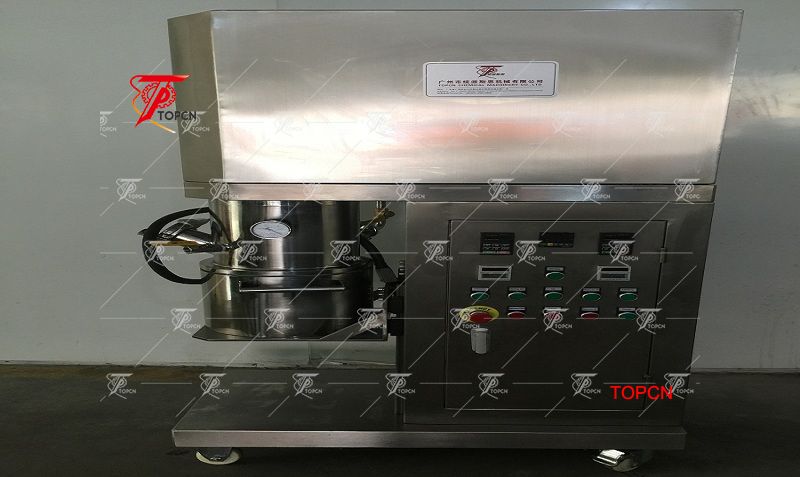

5L High Shear Double Shaft Vacuum Industrial Chemical Mixer

- Application

- Description

- Products Parameters

- Video

- Package&Shipping

- FAQ

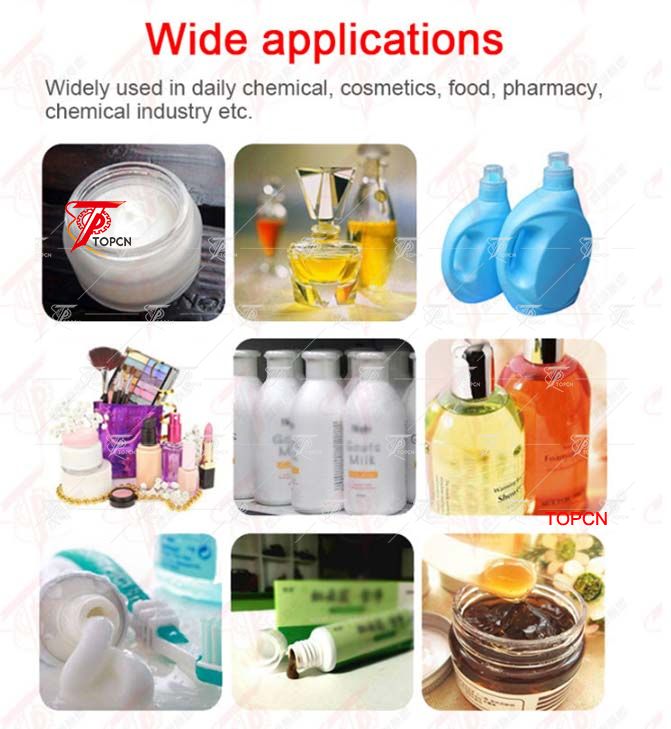

China 5L High Shear Double Shaft Vacuum Industrial Chemical Mixer is widely applied in dispersing paste such as color paint paint, ink, dye, adhesion, ceramic glaze, magnetic recording materials etc. Disperser is the a good solution for mixing, dispersing and dissolving.

5L High Shear Double Shaft Vacuum Industrial Chemical Mixer working principle is Paste Material will be stirred up-down by the high-speed rotation force of disperser/dissolver. Material will be crushed and cut by the impeller and the aggregates will be broken and dispersed rapidly.

Description on the Vacuum Industrial Chemical Mixer purchased respectivly pls link http://www.topcnmachine.com/small-mixer-amp-homogenization/double-shaft-vacuum-industrial-chemical-mixer.html

1). Integrate mixing, dispersion and wall scraper in one machine.

2). Mechanical seal, Oring seal or trapezoid seal for option material reaction can happen under vacuum condition.

3). High and low speed impellers rotate rapidly and exert strong impact force to mix materials thoroughly in a very short time, no deposit and residuals.

4). With jacket or coil-pipe for heating/cooling, medium can be water, electricity, steam or oil.

5). Configured with PLC automatic control system with human-computer interface for option.

6) Planetary Disperser is a powerful dispersing and mixing machine.

7) 5L Double Shaft vacuum mixer combined the theories of traditional double planetary mixer and high speed dispersing mixer, to be an all-round new machine, it has been widely used in many fields at present .

8) This series planetary disperse is special for high viscosity raw materials, for example, sealant, silicone rubber and industrial adhesives.

Type | 5L | 15L | 30L | 50L | 100L | 300L | 500L | 1000L | |||||

Product Name | Double Planetary Mixer | Double Planetary Mixer | |||||||||||

Bucket Size (mm) | Ø280× 180 | Ø280× 325 | Ø400× 325 | Ø480× 365 | Ø550× 550 | Ø850× 650 | Ø960× 810 | Ø1160× 1100 | |||||

Revolution Motor (Kw) | 1.5 | 2.2 | 3 | 4 | 5.5 | 18.5 | 22 | 30-37 | |||||

Revolution Speed (frequency control) r/min | 0-60 | 0-60 | 0-84 | 0-62 | 0-70 | 0-45 | 0-35 | 0-35 | |||||

Rotation Speed (frequency control) r / min | 0-100 | 0-100 | 0-130 | 0-75 | 0-110 | 0-62 | 0-60 | 0-45 | |||||

Dispersing Motor (Kw) | 1.1 | 2.2 | 2.2 | 5.5 | 5.5 | 11 | 30 | 37 | |||||

Vacuum( Mpa) | ≤0.098 | ≤0.098 | ≤0.098 | ≤0.098 | ≤0.098 | ≤0.098 | ≤0.098 | ≤0.098 | |||||

Lifting Stroke(mm) | 360 | 400 | 430 | 650 | 700 | 900 | 1000 | 1100 | |||||

Weight (kg) | 500 | 800 | 1000 | 2000 | 2300 | 2700 | 3500 | 5000 | |||||

Dimensions (mm) | L | 1500 | 1700 | 1700 | 1700 | 1700 | 2500 | 2700 | 2700 | ||||

W | 900 | 900 | 900 | 900 | 1100 | 1200 | 1500 | 1800 | |||||

H | 1700 | 2100 | 2300 | 2300 | 2300 | 2700 | 2900 | 3100 | |||||

600L High Shear Double Shaft Vacuum Industrial Chemical Mixer

60L Planetary Vacuum Mixer Vacuum Toothpaste High Speed Disperser Double Planetary Stirrer Mixer

10L Body Cream Making Machines high shear mixer vacuum homogenizer emulsify blending mixer

20L tilting vacuum homogenizing emulsifiers cream cosmetics machine ,cream homogenize mixer

300L vacuum mixer machine on workshop for cream mixer blending tank emulsifier for lotion cream

dairy cosmetic vacuum high pressure emulsifier homogenizer Oil tank and water tank working video

Main Pot video for mixing equipment high shear vacuum mixer homogenizer for cosmetic soap making

1. DELIVERY LEAD TIME:

30-50WORKING DAYS AFTER RECEIVED DEPOSIT

.

2. TERMS OF PAYMENT:

BY 30% IN ANVANCED, THE BALANCE 70% BY T/T BEFORE SHIPMENT.

3. PRICE VALID UNTIL:

15-20DAYS.

4. PACKING:

WOODEN WITH STRONG SEAWORTHY PACKING SUITABLE FOR EXPORT.

5. PORT OF SHIPMENT:

GUANGZHOU or SHENZHEN PORT.

Q1: Are you a machine manufacturer or trading company?

A1: We are a reliable machine manufacturer that could gives u best service. And our machine can be customized by client's requirement. Welcome to visit our factory!

Q2: How do you guarantee this machine normally operating?

A2: Every machine is tested by our factory and other client before shipping,We will adjust the machine to optimal effect before delivery.And spare is always available and free for you in warranty year.

Q3: How can I install this machine when it arrives?

A3: We will send the engineers overseas to help client installing, commissioning and training.

Q4: Could I choose the language on touch screen?

A4: It's no problem. You can choose Spanish, French, Italian, Arabic, Korean, Japanese and etc,.

Q5: If I need oil and water tank, would you provide for me? How much it cost?

A5: Yes, we could provide oil and water tank for you. The price of oil and water tank depends on the volume of tank.

Q6: Can this mixer programme with flow meter and pumps to realize auto material loading?

A6: Yes, we can offer you Siemens PLC and touch screen to programme auto material loading.

Q7: What kind of product can this machine make?

A7: Emulsifying machine is widely used in producing cream, sauce, wax, shampoo, and etc for food, cosmetic, chemical industry.

Q8: Do you have manual or operation video for us to know more about the machine?

A8: Yes,we will send you the manual and operation video after you ask for us.

Q9: If there's some spare parts that broke,how to solve the problem?

A9: Yes,we will send you the manual and operation video after you ask for us.

Q10: If there's some spare parts that broke,how to solve the problem?

A10: First of all,please take the pic or make a video to show the problem parts.

After the problem is confirm from our sides,we'll send you the spare parts for free,but the shipping cost should be paid by your side.