150kg Soap Extruder Machine

- Application

- Description

- Products Parameters

- Video

- Package&Shipping

- FAQ

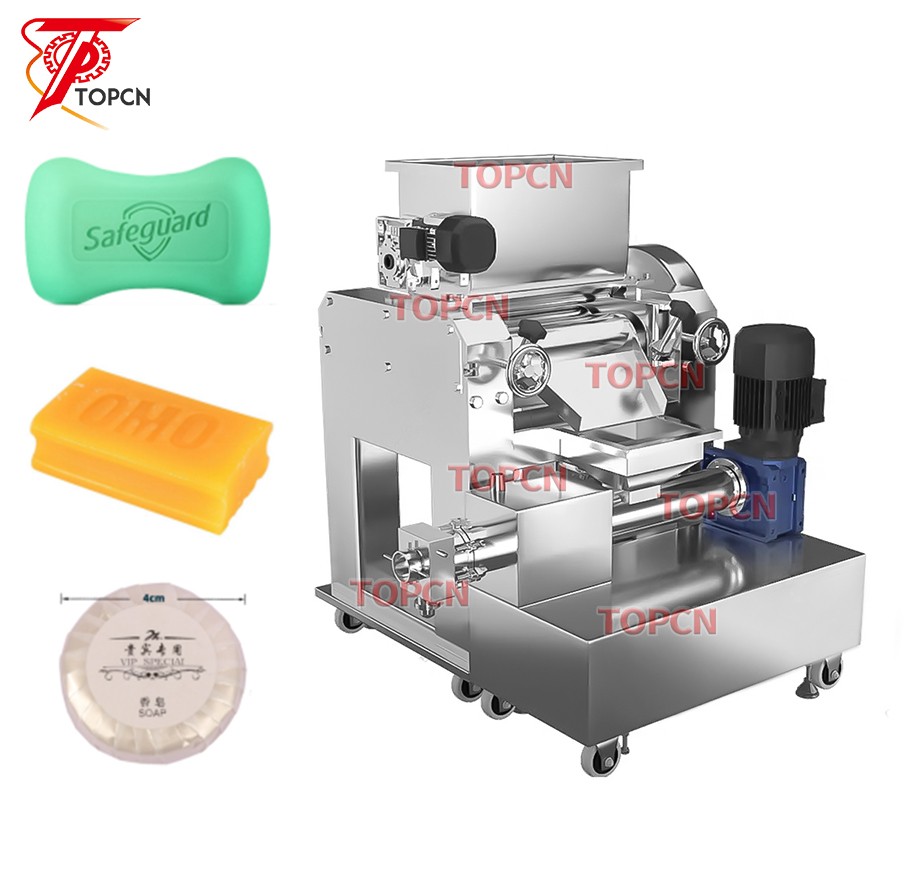

1. This laundry soap production line take soap noodles as raw materials.

2. The production starts with mixing soap noodles and perfume.

3. Then the mixed soap noodles enters in the three roller mill by conveyor belt, where soap thin sheets are made.

4. The soap thin sheet then converted into desired long strip soap by the plodder machine.

4. Then the long strip soap are cut into the soap bars required size by cutting machine(there are two kinds of cutting machine.One is mechanical.The other is automatic).

5. Finally, the soap bars gets packed by packing machine if needed.

6. Soap bars can be made 60g,120g,200g,260g,and so on

I. Technical Specification:

This is our company's new developed machinery line, especially suitable for the one who is new and want to invest into this industry.

The capacity is 150kg/h. It can produce the toilet soap and laundry soap. The main equipment are including mixer, mill, plodder and stamping machine. The advantage for this production line is small investment, simple equipment and convenient operation.

Three Roll Mill (TPS-150) |  |

| Hardened surface of roller surface | |

| Diameter of roller:150mm | |

| Length of roller:300mm | |

| Speed rate of roller:1:3:9 | |

| power consumption:4kw | |

| Material : frame –cast iron | |

| Roller-high Chrome alloy, hard wearing |

| MIXER (TPSM-150) |  |

| Single shaft "Z"type mixer | |

| Mixing time:5-8min/time | |

| Capacity:25kg/time | |

| Revolution:40rpm | |

| Mixing style:Z type | |

| Diameter of roller:Φ450mm | |

| Power:2.2kw | |

| Discharge Mode: Manually |

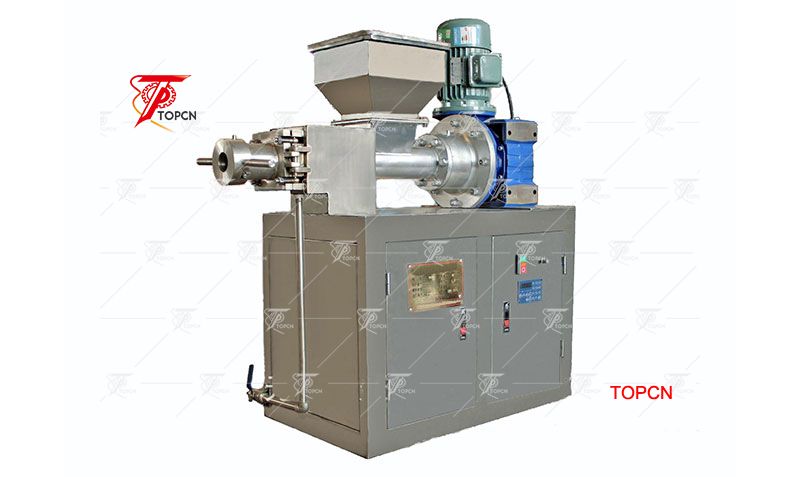

| Soap Extruder (TPVP-150) |  |

| Capacity:150kg/h | |

| Diameter of roller:Φ140mm | |

| Revolution:10-23r/min (speed adjustable) | |

| Power:4kw | |

| Material:fame-Q235 carbon steel 60 splicer made, the part reached by soap noodle- stainless steel. |

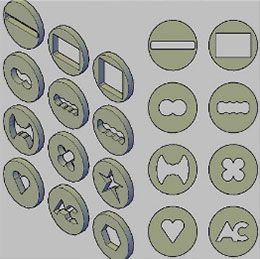

| Hydraulic Stamping MacHine |  |

| Soap weight:under 200g | |

| Speed:10-60time/min | |

| Stroke:70-120mm (adjustable) | |

| power:2.2kw | |

| Material:frame----good quality Q235carbon steel,the part reached by soap noodle –stainless steel | |

| Overall size:790mm×790mm×1580mm | |

| G.W.:250kg |

Quality Details:

| Frame----good quality Q235carbon steel |

| The part reached by soap noodle –stainless steel | |

| The top part with exhaust fan. | |

| Screw body-stainless steel | |

| It adopts hard tooth surface reducer. |  |

| Screw body with cooling jacket. | |

| Exit with heater device. | |

| Shaping plate as per Customer specifications. |

| Maximum output: Ø 75 mm | |

| The extrusion screws have a diameter of 80 or 120 mm |  |

| Screw body with stainless steel | |

| Variable screw speed |

| Ⅰ. Function | ||

| S20 soap mixer is mainly used to mix the soap flakes in daily chemical factories specialized in toilet soap production. It also can be used in other chemical industry semi-powder, non consistency of the mixing and mixing of the material. | ||

| Ⅱ. Major technical parameters | ||

| Production Capacity(kg per time) | >15 | |

| Volume(L) | 46 | |

| Stirring spindle speed(revolutions per minute) | 46 | |

| Pneumatic pressure (Mpa) | 0.4-0.8 | |

| Power of motor(kw) | 0.75 | |

| Size (mm) | 950×460×920 | |

| Weight (kg) | 400 | |

| Model | S150 | |

| Reference | ||

| Diameter of rollers mm | Φ150 | |

| Working length of rollers mm | 300 | |

| Revolution speed of rollers r.p.m | Slow speed roller | 25.3 |

| Medium speed roller | 63.25 | |

| Fast speed roller | 152 | |

| Motor | Model | Y100-4 |

| Power KW | 2.2 | |

| Revolution speed r.p.m | 1420 | |

| Speed ratio of rollers | 02:06. | |

| Size L×W×h | 820×800×920 | |

| Weight kg | 600 | |

| Ⅰ. Function | ||

| This plodder is used for extruding the soap noodles to be soap bar for stamping machine, for the soap shape, it could follow customer requirement to change the size of the extruding hole. | ||

| Ⅱ. Major technical parameters | ||

| Output capacity(cpm) | 80 | |

| Screw diameter(mm) | Φ110 | |

| Screw speed(rpm) | 43 | |

| Power(kw) | 2.2 | |

| Size(mm) | 950×400×1100 | |

| Ⅰ. Function | ||

| This stamping machine is used for stamping the soaps to be shape as customer requirement. This machine is drived by motor and two wheel, the punching head drived by crankshaft, there is clutch near the crankshaft, it is for manual operation. When it work, worker put the soap bar from plodder onto the positioning plate of punching mold, then tread the pedal and loose. Then clutch close and the big wheel would drive the punching head and start working. The crankshaft work for one cycle and stop, it finish one cycle. If tread the pedal continuously, punching head will stamp continuously also. | ||

| Ⅱ. Major technical parameters | ||

| Speed(times per minute) | 160 | |

| Output capacity(cpm) | 20 | |

| Soap weight(g) | 20-60 | |

| Punching height(mm) | 52 | |

| Power(kw) | 1.5 | |

| Size(mm) | 600×430×1220 | |

| Plateform height(mm) | 90 | |

| Weight(kg) | 500 | |

Q: What should I do to choose the best machine for us?

A: 1) Tell me the material you want to fill, we'll choose the suitable type of machine for you to consider.

2) After choose the suitable type of machine, then tell me the filling capacity you need for the machine.

3) At last tell me the inner diameter of your container to help us choose the best diameter of the package wrapping head.

Q: What thickness of the Film?

A: 0.022-0.03mm film package effect is good.

Q: What material of the Film?

A: Pearl Film, Phosphorus film paper, BOPP film.

Q: Do you have manual or operation video for us to know more about the machine?

A: Yes, we will send you the manual and operation video after you ask for us.

Q: If there's some spare parts that broke,how to solve the problem?

A: Yes, we will send you the manual and operation video after you ask for us.

Q: If there's some spare parts that broke,how to solve the problem?

A: First of all, please take the pic or make a video to show the problem parts.

After the problem is confirm from our sides, we'll send you the spare parts for free, but the shipping cost should be paid by your side.