Ultrasonic Soft Tube Filling and Sealing Machine

- Application

- Description

- Products Parameters

- Video

- Package&Shipping

- FAQ

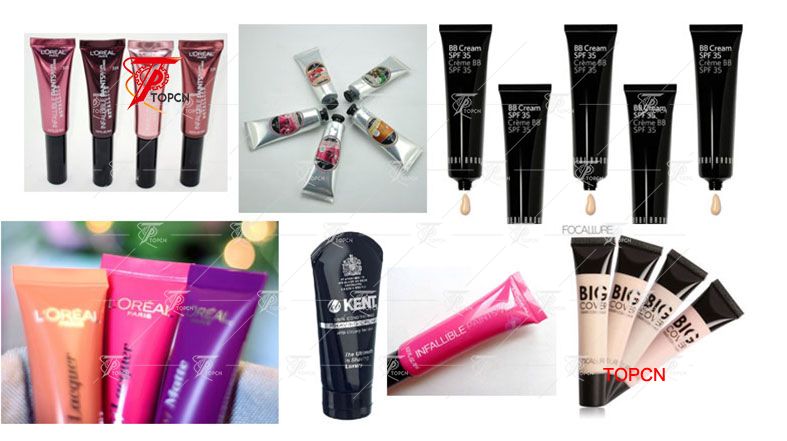

Suitable for plastic tube filling and welding in the field of cosmetic, medicine, commodity, hardware, etc.

1. To replace the traditional welding or bonding process, low cost, clean pollution-free and does not damage the plastic tube.

2. Intelligent automatic frequency tracking system, which can recognize the vibration frequency of the ultrasonic system automatically, so as to effectively protect the mold. Large output, small noise, stable performance, long life.

3. High welding strength, Good sealing performance, the strength of welding area is same as other area of the plastic.

4. Stable welding process, easy operation, easy maintenance.

5. Adopting PLC controller, easy to operate, auto-protecting system can avoid the damage caused by improper operation.

7. Four points balance adjustment, easy to adjust the welding head.

8. aluminum/titanium radial pole, sonic, strong stability.

9. Auto filling, orientate, welding, cutting, filling is stable and accurate and noiseless.

Using ultrasonic vibration to weld the tail of plastic tube, the strength of welding area is same as other area of the plastic. No need adhesive or heating, Replace the traditional hot pressing or bonding process, Low cost and no pollution and no damage to plastic tube

| Model | TP-2015TF |

| Power supply | AC220V |

| Power | 1500W |

| Frequency | 20KHZ |

| Tube length | 50~250mm |

| Tube diameter | 10~50mm |

| Filling range | 10~250ml |

| Machine size | 860*620*1300mm |

| Net weight | 95KGs |

1. DELIVERY LEAD TIME:

70-10 WORKING DAYS AFTER RECEIVED DEPOSIT.

2. TERMS OF PAYMENT:

BY 30% IN ANVANCED, THE BALANCE 70% BY T/T BEFORE SHIPMENT.

3. PRICE VALID UNTIL:

15-20DAYS.

4. PACKING:

WOODEN WITH STRONG SEAWORTHY PACKING SUITABLE FOR EXPORT.

5. PORT OF SHIPMENT:

GUANGZHOU or SHENZHEN PORT.

Q1: Are you a machine manufacturer or trading company?

A1: We are a reliable machine manufacturer that could gives u best service. And our machine can be customized by client's requirement. Welcome to visit our factory!

Q2: How do you guarantee this machine normally operating?

A2: Every machine is tested by our factory and other client before shipping,We will adjust the machine to optimal effect before delivery.And spare is always available and free for you in warranty year.

Q3: How can I install this machine when it arrives?

A3: We will send the engineers overseas to help client installing, commissioning and training.

Q4: Could I choose the language on touch screen?

A4: It's no problem. You can choose Spanish, French, Italian, Arabic, Korean, Japanese and etc,.

Q5: If i have many size tube, could them can use in one machine?

A5: Of course they can, we update the tech for design the metal tube holder/base for suiting any size and adjust the mold.

Q6: I have own material, is it no problem in tube filling and sealing?

A6: No any problem, we have designed for more than 150pcs different material. We design the machine by your material, like update in SUS316, Explosion-proof, high speed two filling head filling and so on.

Q7: Do you have manual or operation video for us to know more about the machine?

A7: Yes,we will send you the manual and operation video after you ask for us.

Q8: If there's some spare parts that broke,how to solve the problem?

A8: Yes,we will send you the manual and operation video after you ask for us.

Q9: If there's some spare parts that broke,how to solve the problem?

A9: First of all,please take the pic or make a video to show the problem parts.

After the problem is confirm from our sides,we'll send you the spare parts for free,but the shipping cost should be paid by your side.