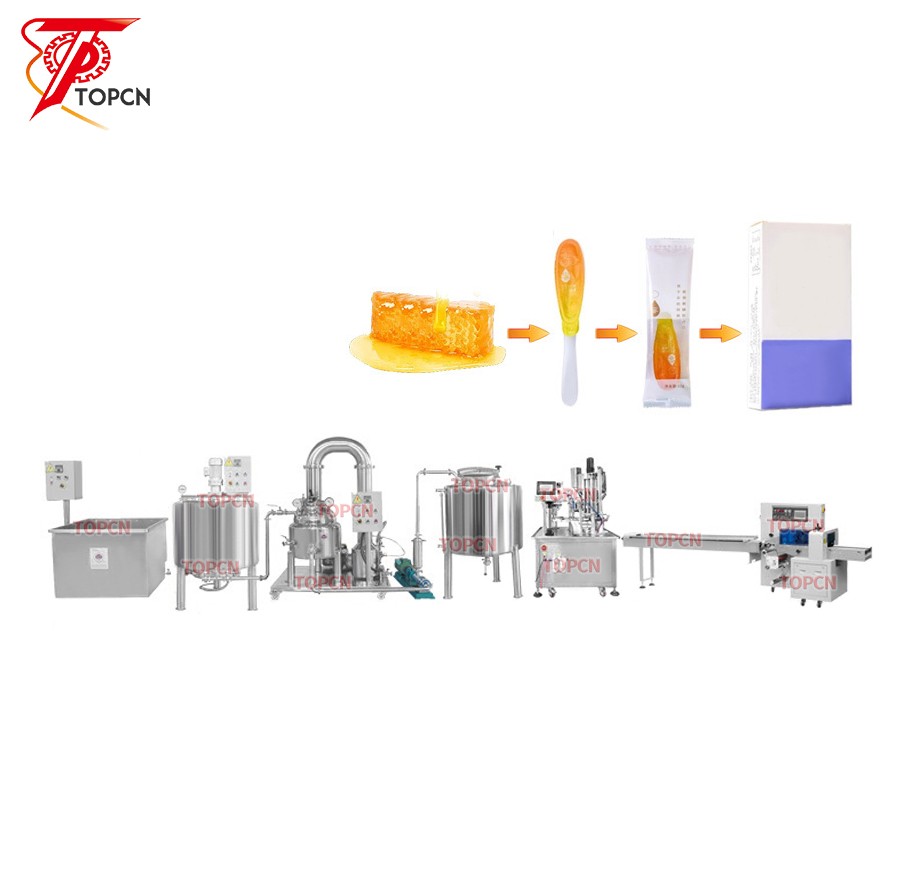

Monoblock Cosmetic Essential Oil Serum Dropper Bottle Automatic Filling Capping and Shrink Sleeve Labeling Production Line

- Application

- Description

- Products Parameters

- Video

- Package&Shipping

- FAQ

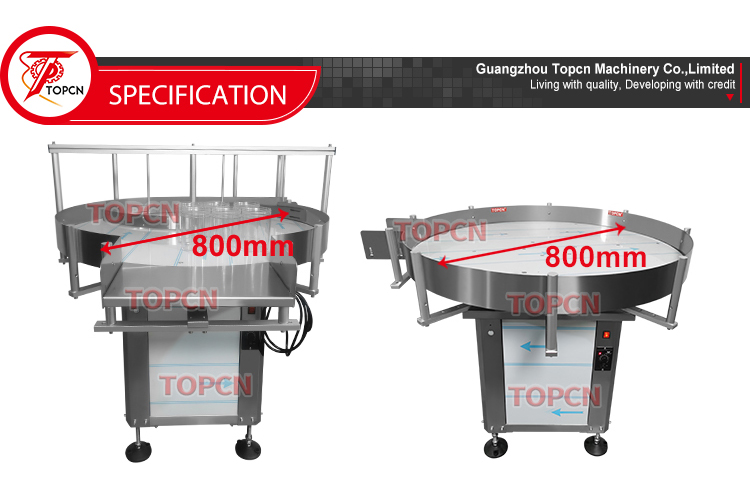

Product Name | Bottle feeding turntable | |||

Model | TP-LP800 | TP-LP1000 | TP-LP-1200 | |

Turntable Diameter | 800mm | 1000mm | 1200mm | |

Suitable Bottle Diameter | 20-100mm | |||

Suitable Bottle Height | 30-120mm | |||

Working Speed | 40-60 bottles/min(depends on bottle size) | |||

Motor Power | 0.2KW | |||

Power Supply | 220V/50-60HZ | |||

Net Weight | 109.5kg | 135kg | 165kg | |

Machine size | 95*100*110cm | 115*120*110cm | 135*130*110cm | |

Package Size | 115*100*132cm | 135*131.5*132cm | 155*150*132cm | |

Gross Weight | 155kg | 180kg | 200kg | |

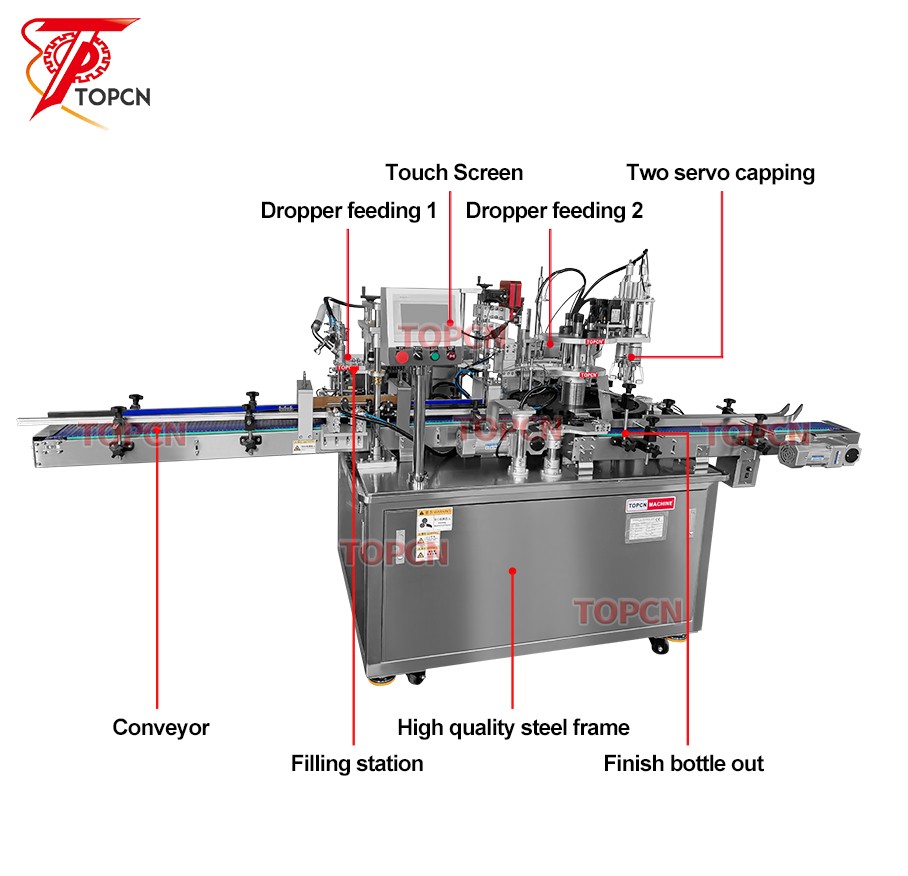

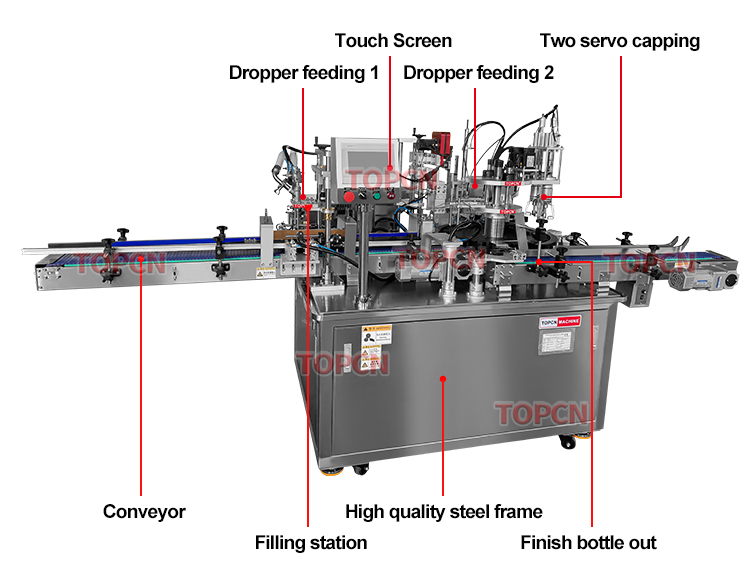

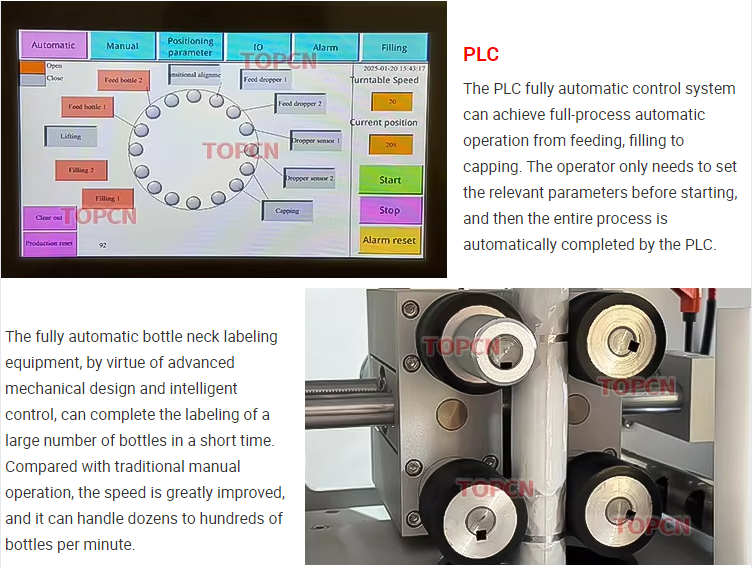

1.TOPCN drop glass bottle oil machine, cbd oil filling capping labeling machine, adopt piston filling method, controlled by micro-computer, filling accurate. (Can be changed to ceramic pump for special work surroundings).

2. Adopt advanced electrical and pneumatic parts, ensure stable work ability and long use time, high filling precision, capping qualified rate.

3. Achieve no bottle, no filling; No bottle no capping, No leak, no drool during filling process. Reduce detergent material consumption, increase user's economic benefit.

4. User can adjust speed and filling volume by touch screen setting. Easy to use, to clean, to adjust, to maintain.

5. Can be matched with protective cover to forbid pollution.

6. Connected to the liquid container through corrosion-resistant medical infusion tube.

7. Can work alone or connected to labeling machine to work together.

8. Can be matched with wheels to move the machine easily.

Filling volume | 10-250ml(adjustable) |

Filling type | Servo magnetic pump filling |

Filling material | Essence liquid |

Filling precision | 0.5% |

Capacity | 40-50 BPM |

Air consumption | 0.6—0.8mpa |

Power | 5.5KW( 220V 50Hz) |

Machine size | 3200×1700×1500(mm) |

N.W | About 800kg |

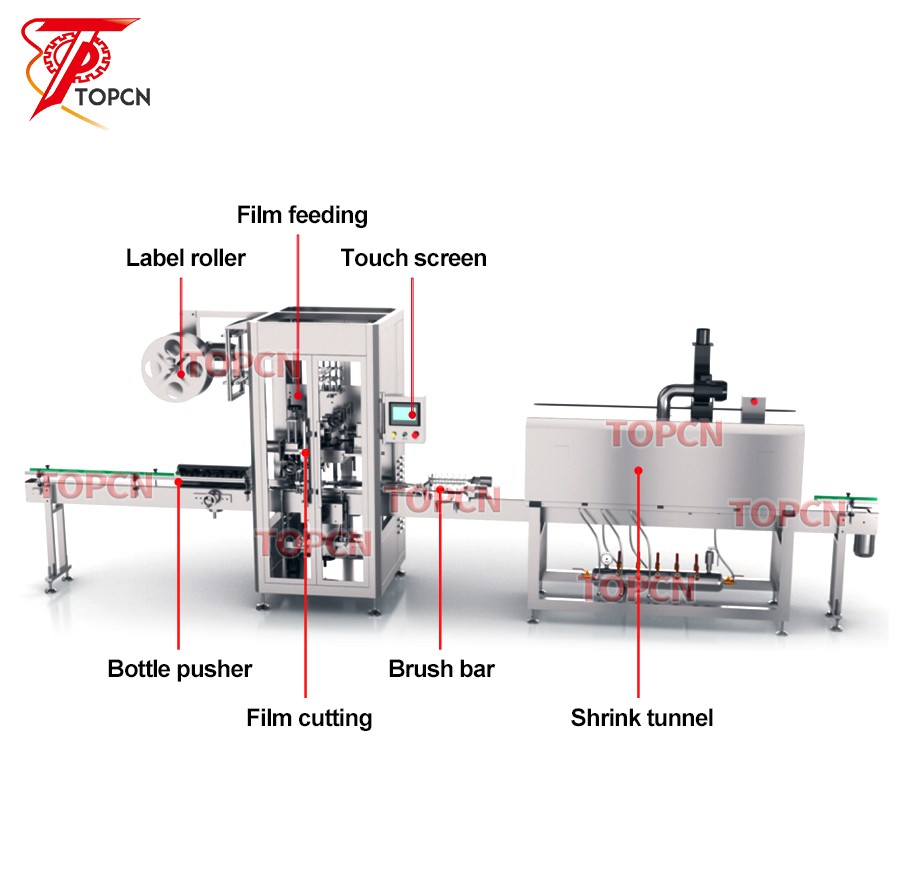

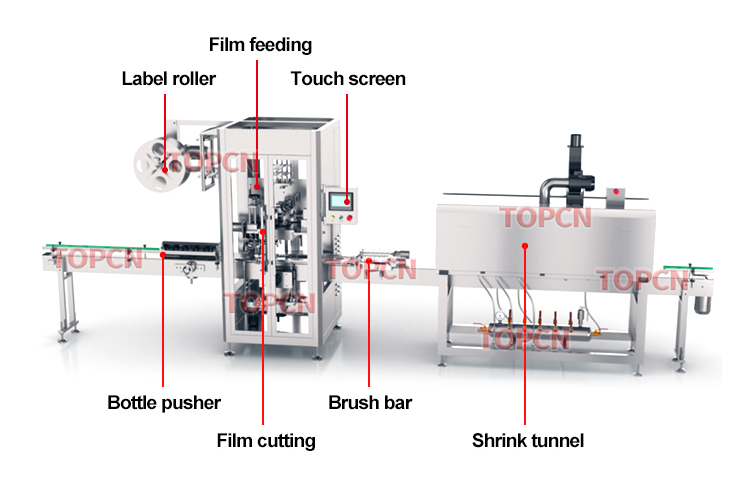

Machine model | TPLM-S |

Bottle diameter range | φ28mm-φ125mm (can be customized) |

Bottle height | 30mm ~ 280mm (can be customized) |

Label length | 30mm~250mm (can be customized) |

Label thickness | 0.03 mm ~ 0.13 mm (PVC, PET, OPS, materials are all available) |

Sleeve standard error | +1.5mm |

Paper tube inner diameter | 5"~10" (can be adjusted) |

Machine speed | 150 bottles/min (based on label length) |

Voltage | 220V Single Phase |

Power | 15KW |

Conveyor belt | standard 2M |

Machine size | About 2950*10301870mm(L*W*H) |

Machine weight | About 464kg |

Shrink Tunnel | |

Tunnel length | About 1800mm |

Tunnel width | About 395mm |

Tunnel height | About 360mm |

Suitable bottle diameter | ≤80mm |

Conveyor height | About 900mm |

Machine size | About 3050*480*1330mm(L*W*H) |

Machine weight | About 86kg |

Package size | About 1905*610*1720mm |

Package weight | About 143kg |

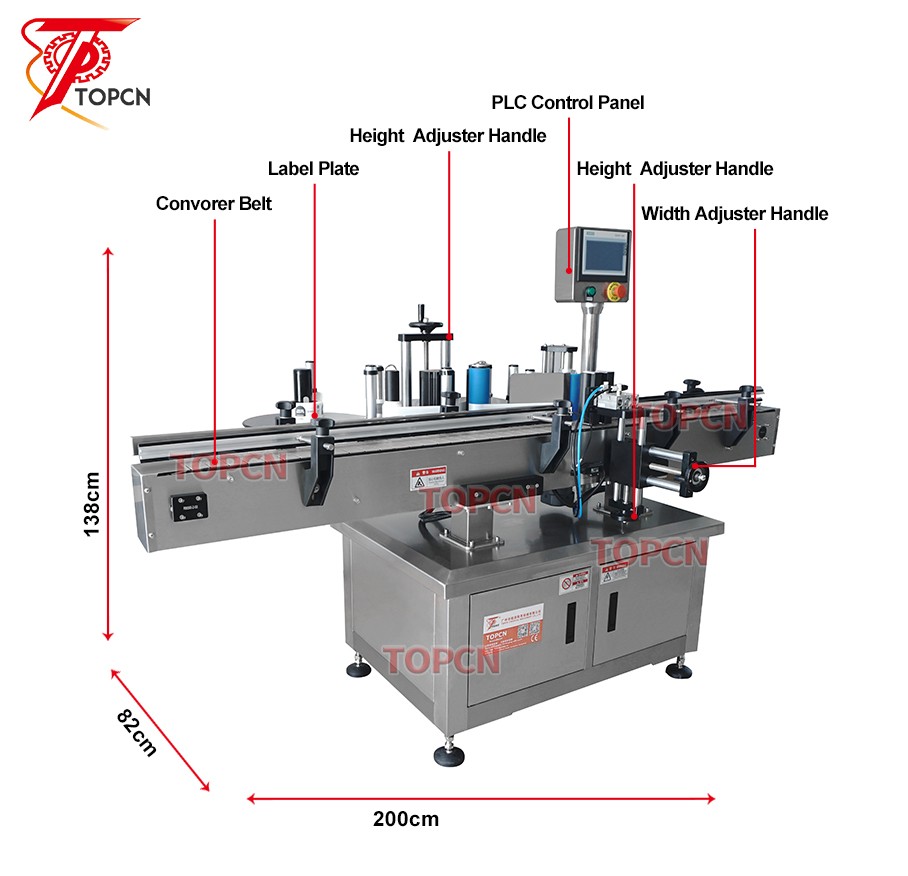

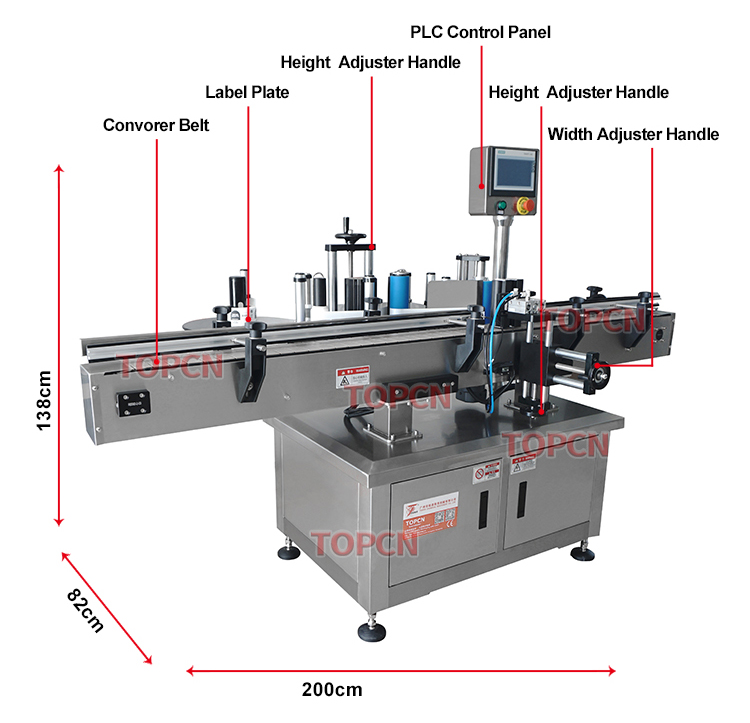

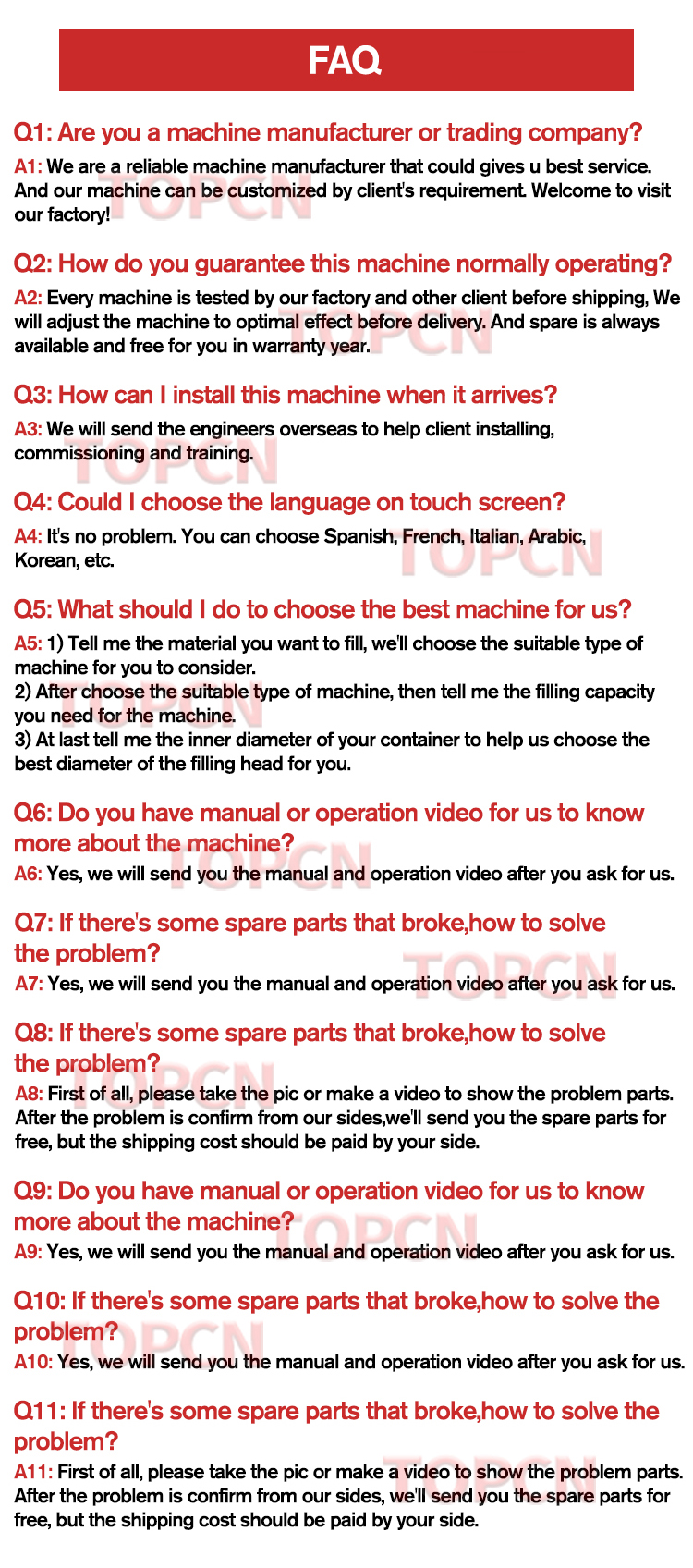

Labeling Precision | ±1mm (excluding product and label error); |

Power Supply | AC220V 50/60Hz 700W |

Conveyor Speed | 5~25 meters/minute; |

Labeling Speed | 10~35pcs/min(Related to product, label size); |

Sticker Out-Come Speed | Stepping Motor: 5~19 meters/minute |

Servo Motor: 5~25 meters/minute | |

Application Bottle Size | External diameter: Φ25-100mm; |

Height: 25mm~300mm; | |

Applicable label size | Label Length: 20mm~290mm; |

Label Width(body paper width): 20mm~120mm; 180mm (option) | |

Inner dia. of paper roll | Φ76mm |

External dia. of paper roll | Max. Φ300mm |

Size (LXWXH) | 2000mm×1150mm×1600mm |

Weight | 185kgs |

- 1L 5L Four Heads Engine Motor Oil Water Tacking Filling Line Skincare Shampoo Detergent Viscous Liquid Paste Tracking Filling Machine

- Automatic Linear 5L 20L HDPE Bottle Jerry Can Lubricating Motor Lubricant Lube Oil Weighing Filling Line

- Automatic Tomato Ketchup Jam Jar Paste Chili Sauce Bottle Filler Tabletop Filling Capping and Labeling Machine Production Line

- Automatic Small Liquid Fruit Juice Filling Capping Line Grape Vodka Whisky Alcohol Wine Filling Machine Line

- Eight Head Magnetic Pump 3 In 1 Rotary Engine Oil Liquid Filling Capping And Labeling Machine Line

- Pneumatic 10 Heads Perfume Jar Filling and Bottle Crimping Machine 30-100ml Small Vial Perfume Filler Machine

- Fully Automatic Glass Bottle Ketchup Jam Peanut Butter Chili Sauce Filling Machine Line

- Automatic Whisky Health Wine Syrup Produciton Line Alcohol Syrup Bottle Filling Capping Machine

- Automatic Warming Food Heater Cooking wax gel liquid Heat Tin Can Dish Fuel Filling and Press Capping Machine

- Laundry Detergent Dish Soap Dish washing Liquid Paste Gel Bottles Gear Pump Filling Capping Laeling Machine Production Line

- Top Quality Oil Chemical Liquid Refill Line Bottle Vegetable Oil Filling Capping Labeling Machine/plant/line

- Automatic bottle filling beer fruit juice milk production line price

- Honey Processing Equipment Honey Filtering Extractor Preheating Processing Packing Machines

- Automatic Liquid Edible Oil Cooking Oil Eengine Oil Bottle fFilling Capping Machine Labeling Production Line